Accessories

Different options for different need

For our machines, we have a large range of accessories that definitely also meet your needs.

See our range of accessories

Click on the tabs to see more.

Oil separator

Our oil separators is effective at collecting oil or grease in the water surface. We have a larger selection of different types of oil separator, depending on the task and needs.

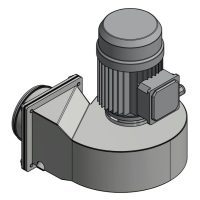

Exhaust

Our range of ventilators is used to suck out water vapor during or after the end of the washing cycle. We have different sizes of ventilators for our washing system, depending on the machine size.

Pressure filter

Our pressure filters consist of two types – pressure filters with bag filter insert or pressure filters with cartridge insert.

Blow-off

To blow-off the parts for most of the water or minimize spillage in our washers, you can choose a solution with compressed air or a ring chamber fan.

Week timer

The week timer is for controlling heaters and possibly oil separator. Set your system to when it should turn off- and on, both heaters and oil separator, all days of the week. Can also be controlled via Bluetooth.

Chemical dosing

A chemical dosing is a good option to add to the washer, as it seeks to maintain the optimal soap concentration during operation.

Automatic water filling

Avoid constantly filling the system manually with water. By adding automatic water filling, the plant itself seeks to add more water when the water level is too low.

Bilge pump

Our bilge pumps are typically selected if you need to empty the tanks into an external tank or above level.

Light tower

A light tower is a good option for your washing system, if you need to be able to see from a distance whether the system is in operation, finished with the washing cycle or has stopped due to faults.

PLC

If you need to have a little more control over the different washing processes, you can add a PLC and a touch screen. (Compo Cleener and Twin Cleener, comes standard with PLC and Touchscreen)

High pressure pump

If you have the need to wash your parts with high-pressure, you can choose to have a high-pressure pump fitted.

Drip tray

If there is an accident, it is nice to have a safety drip tray – so that the water does not get further into production.

Inlet / outlet

Decide for yourself how far the inlet and outlet should be on the machine. Or if the need arises, add a runway before and after the washing system.

Transporter

Our transporter is a good solution if you have many smaller items to be fed to the inlet.

Conveyor belt

For our Compo Cleener, there is a large selection of different types of conveyor belts, depending on need.

Turntable

Our turntable is a good option for our Compo Cleener, if you need a simple way to collect more items that comes from the outlet after the end of the wash cycle.

Torque limiter

The torque limiter is a safety measure you can add, in the event that an item may get stuck during operation – and thus avoid something being torn apart.

Transport trolley

For our frontloaders, we recommend that you choose a transport trolley or loading ramp to be able to pull the entire work grate out after washing. Being able to pull out the entire grate contributes to a better working position. The transport trolley is the obvious choice if you need to transport the items before or after washing.

Loading ramp

For our front loaders, we recommend that you choose a loading ramp or transport trolley to be able to pull out the entire work grate after washing. Being able to pull out the entire grate contributes to a better working position. The charging ramp is the obvious choice if you do not need to transport the items before or after washing.

Double door

On our frontloaders, it is possible to make the cabin through. This solution makes it possible to load the washing system from one side, and unload it from the other side of the washing system. This is done by fitting an extra pneumatic door on the back of the system.

Gear motor drive for nozzle tubes

As standard on our DF models, nozzle touches rotate via the nozzle pressure. However, if you have many different sizes of parts, we recommend that you get gearmotor mounted on the upper nozzle boom. The gear motor thus ensures that the nozzle boom always rotates at a steady pace – and thereby also achieves a better washing result. (This option is not suitable for our Twin Cleener™, as it comes standard with square washing system via chain drive)

Drum device

Our frontloaders can also be fitted with a 2- or 4-curve system, which rotates inside the cabin. This option can be a good solution if you have many small items to wash.

Gear motor drive on basket

As standard, our toploader models rotates the washing basket via the nozzle pressure. However, if you have many different sizes of items, we recommend that you get a gear motor drive mounted on the basket. The gear motor thus ensures that the washing basket always rotates at a steady pace – and thereby also achieves a better washing result.

Drum device

Our toploaders can also be fitted with a 1- or 2 basket drum device, which rotates inside the cabin. This option can be a good solution if you have many small items to wash.

Washer mounted on wheels

On our RT 700, it is possible to have wheels mounted on the machine feet – so if you need to be able to place this washer in different places in production, this option makes it a little easier.

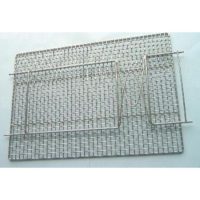

Heavy-duty stainless steel basket

This type of basket is made of strong stainless steel. The basket has handles and can be stacked. It is available in different sizes.

Lid for heavy-duty basket

For the RK basket, there are also different types of lids – regular lids or adjustable lids.

Mini basket with lid

This basket is made of thin stainless steel. The basket comes with a lid and is only available in one size.

Mini basket without lid

This basket is made of thin stainless steel. The basket has no associated lid and is only available in one size.